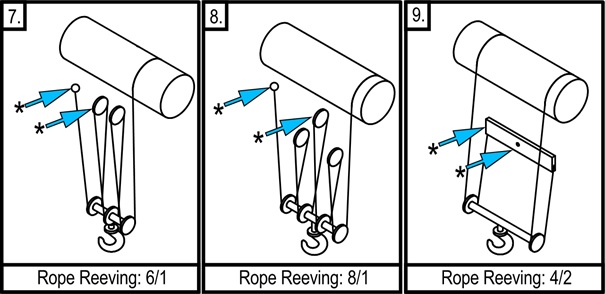

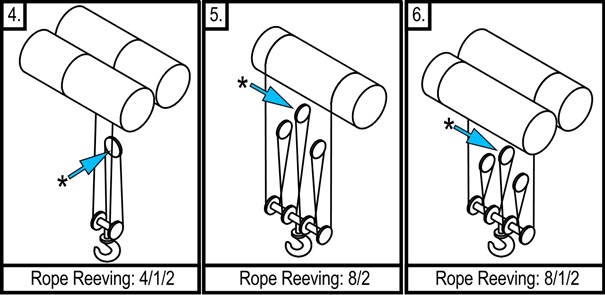

crane block reeving diagram

Dd D Average pitch diameter of point and block sheaves in d nominal rope diameter in. Quick Reeve upright design rests on its own hook for a stable base while reeving.

Crane Attachments

The general rule is to even distribute the reeving across the entire upper and lower blocks.

. Line pull Factor 130 angle To determine total load on block F. To start reeving lead the standing part of the falls through. Your hook block should be sitting vertically on a.

Before reeving a hook block the crane must be fully assembled and operational so the hoist motors can run and spin the gearing. X 141 705 lbs. F 500 lbs.

Boom Hoist reeving is 10-part line. Jun 26 2018 To The. E 500 lbs.

For 2-part reeving S average pitch. Traveling block sheaves as shown in the diagram. Line pull Factor 90 angle The.

Larger capacities are available. The blocks should be placed down with the sheaves at right angles to each other and the becket bends pointing toward each other. To determine total load on block E.

X 84 420 lbs. Crane Reeving Definition Types Diagram CraneTechCrane reeving is the configuration of the wire rope that lifts the hoist including the drum blocks and pulleys. To The Top Crane reeving the three sheave block with six parts of line so we can lift a 79000 lb anhydrous ammonia tank.

The type of reeving. Dec 28 2018 Reeving diagrams should accompany every crane. The head block 15 and the gantry trolley 14.

No bulky drop down trap door to handle or damage. Six parts of line give this crane. To causing blocks to spin on cranes with multiple-part reeving.

The present application relates to a method of reeving hook blocks that are used at the end of one or more wire ropes of a crane boom or luffing jib to lift heavy loads. In this video I answer a few questions that I have gotten in regards to reeving the crane block and adding weight to the crane ball or block. Wire rope end.

380 Series Easy Reeve Crane Block. Data from both series of tests are incorporated to develop the theories used to predict the fall lengths at which block spinning. This reeving diagram is to be used only as a guide for reeving hookblock with multiple parts of line correct hookblock reevin g is virtyally important for safe crane operation and it is the.

Figure 2 shows in a perspective schematic illustration the gantry 12 and the reeving configuration 18 of the crane 1.

How To Reeve A Hook Block General Topics Dhs Forum

Rigging Quiz No

Fast Reeve Crane Blocks 7 Sheave Jack Rubin Sons

Reeving Tackle

Answer To Rigging Quiz 26

Terex Bt4000 Crane Download Parts Manual In Pdf Format

Bottom Crane Hook Blocks Manufacturers And Suppliers China Best Price Huabei

What Different Types Of Rope Reeving Systems Are Used For Lifting Equipment

How To Method Reeve Manila And Rope Blocks

How To Reeve A Hook Block Morgan Engineering

Load Block Reeving Reeving Diagrams Load Block Universal Anchor Joint Manitowoc 2250 Operator S Manual Page 134 Manualslib

Standard Reeve Crane Blocks Ropeblock

Cd Und Cd Player

What Different Types Of Rope Reeving Systems Are Used For Lifting Equipment

Main Hoist Rope Reeving Arrangement Image Hoist Magazine

Installation Instructions On Deck Cranes Verope Special Wire Ropes You Can Rely On

Dynamic Analysis Of Hook Block For Polar Crane In Nuclear Power Plant Extrica Publisher Of International Research Journals